You could say that with this masterworks exhibition I actually succumbed to commerce. When I started more than thirty years ago, I wanted to design furniture that was affordable for “normal” people. That is terribly difficult, especially because we make very small numbers and often even single pieces. All this time we have focused on making a good and affordable product and built up an incredible amount of knowledge and skill.

About ten years ago, because I didn’t want to throw away material, we started making even more labor intensive objects. Again, a move toward more exclusivity proved to be embraced. During a dinner with David in the Lobby of our hotel he made the link between the most and least labor-intensive objects; they are actually all masterpieces, but what would be the next step?

Whereas with our “normal” collection we use all our skill to make a good and affordable product (as far as it is possible), with this masterworks collection we put all our effort into working at the limit of what we can work with or even over it! The masterpieces are the result of a lifetime of pushing the limits and learning!

Visit our exhibition MASTERWORKS at The Future Perfect in New York from 12 September to 25 October.

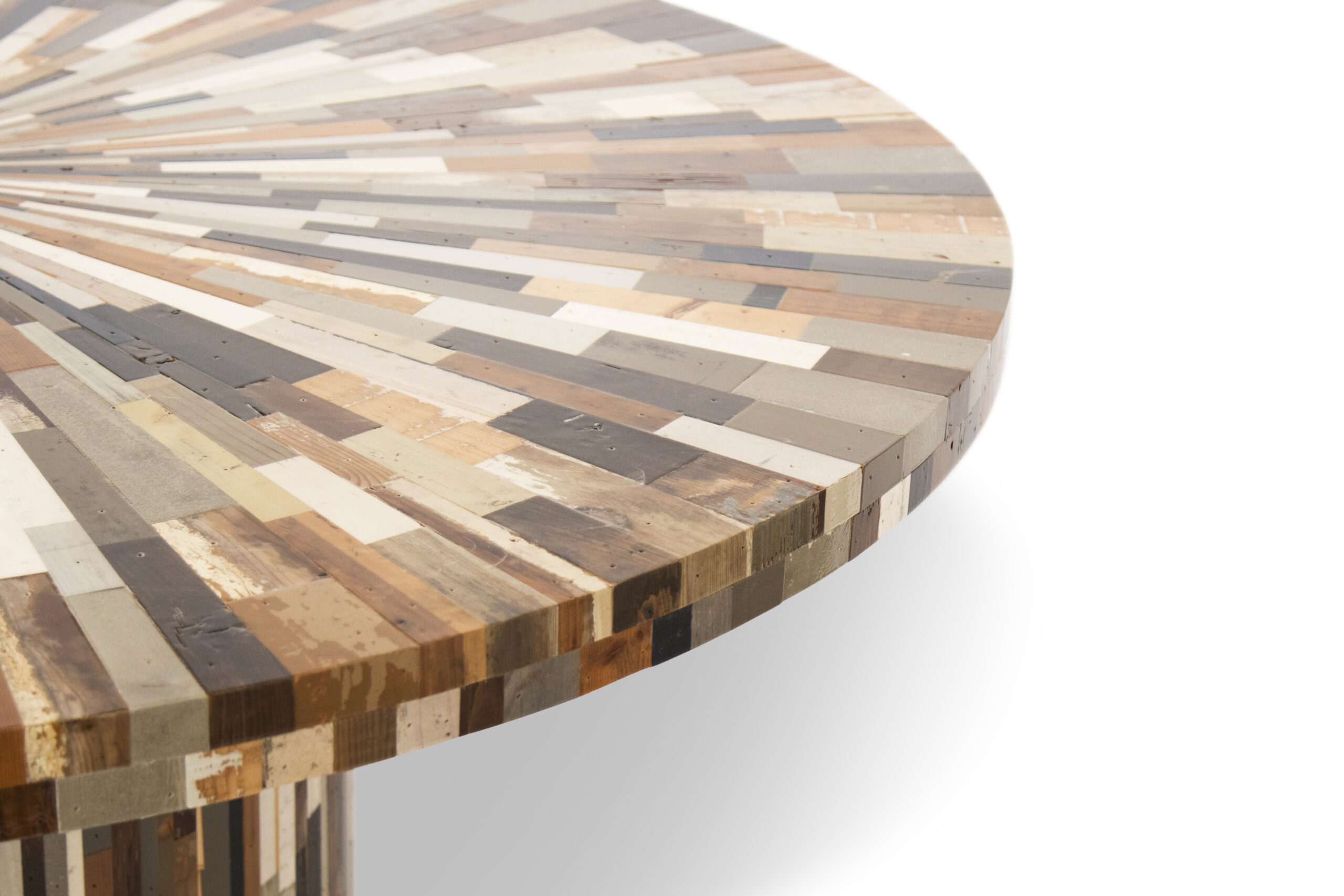

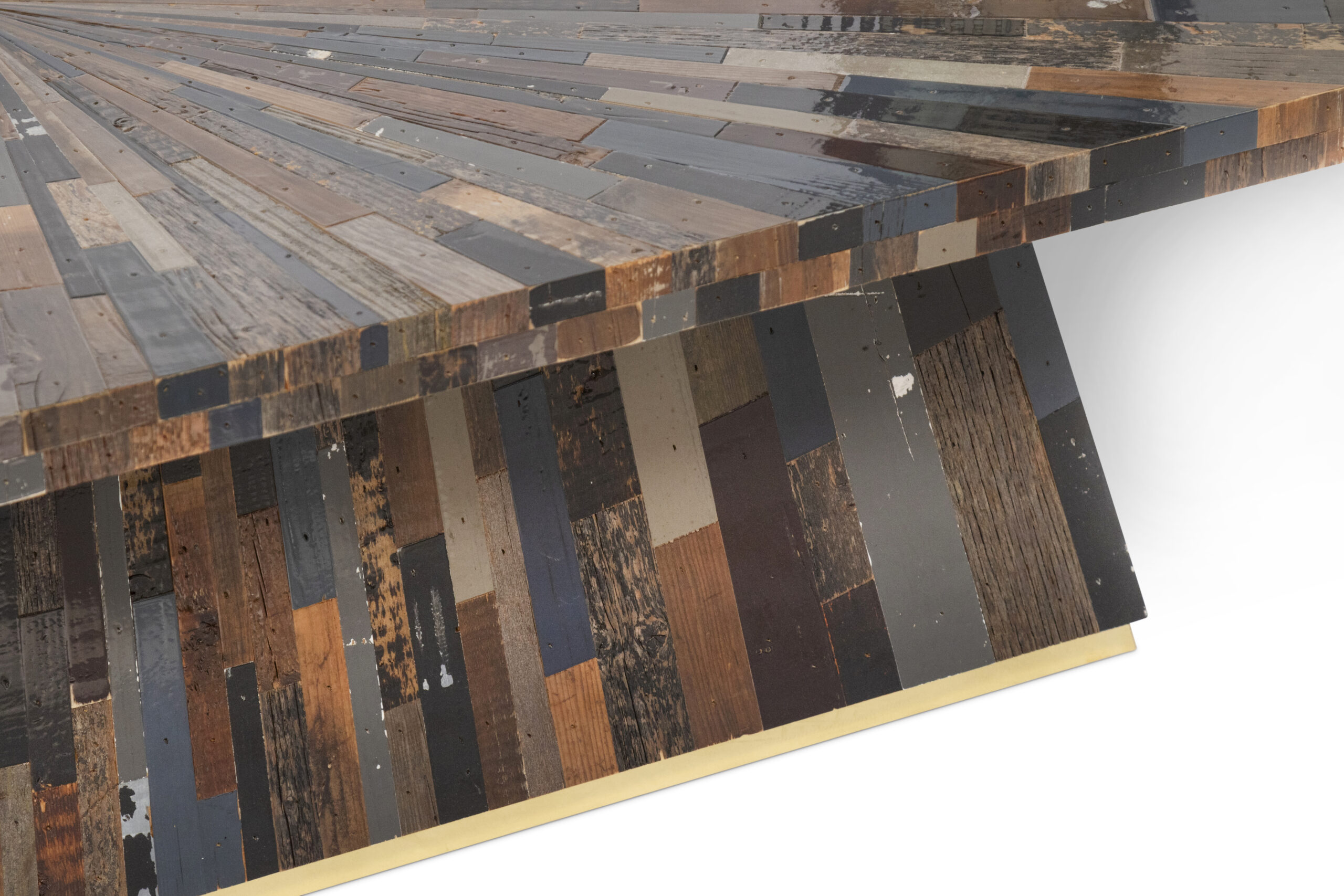

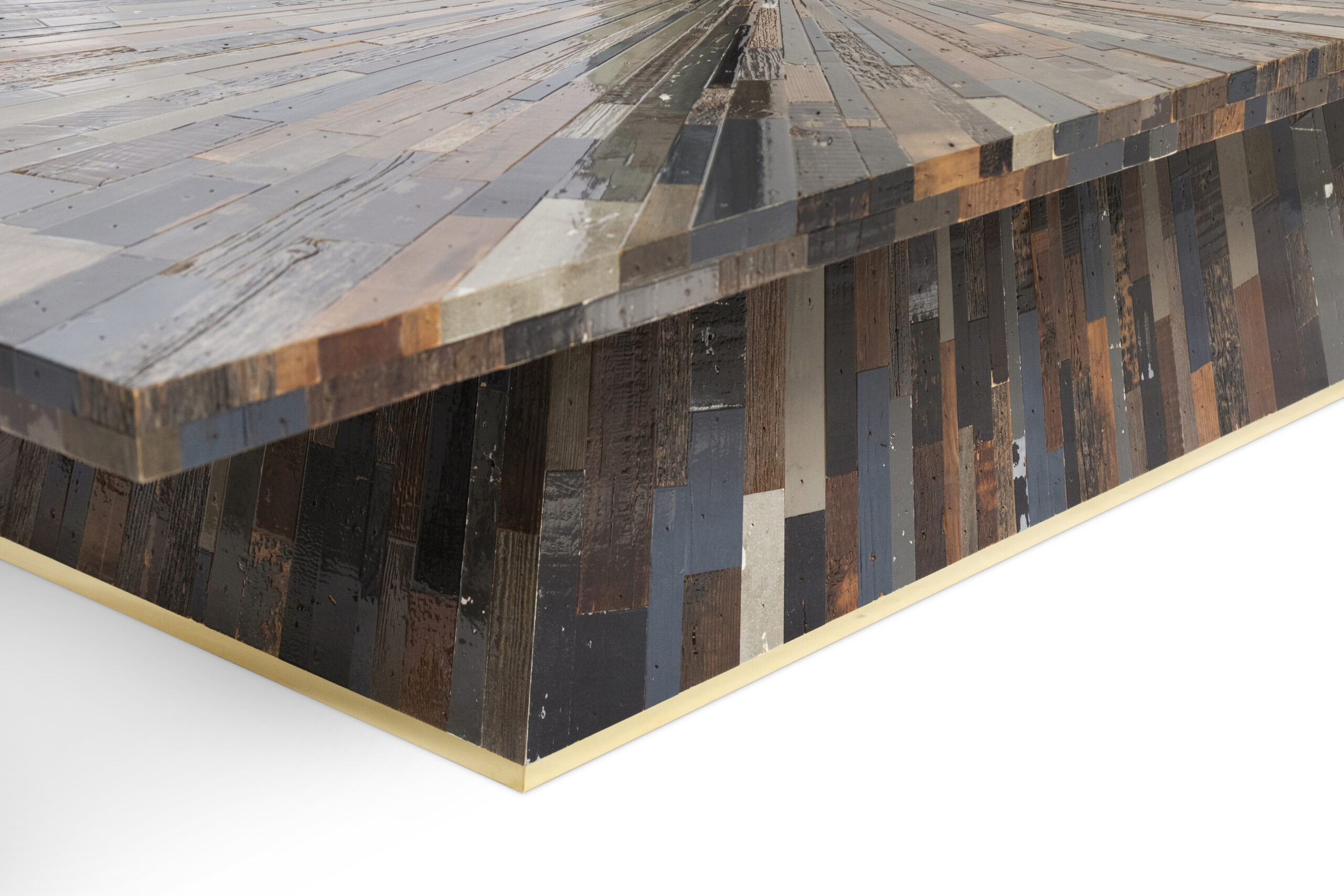

Waste-Waste-Waste Round Table in Scrapwood

70 x 70 Crumbling Cabinet in Scrapwood

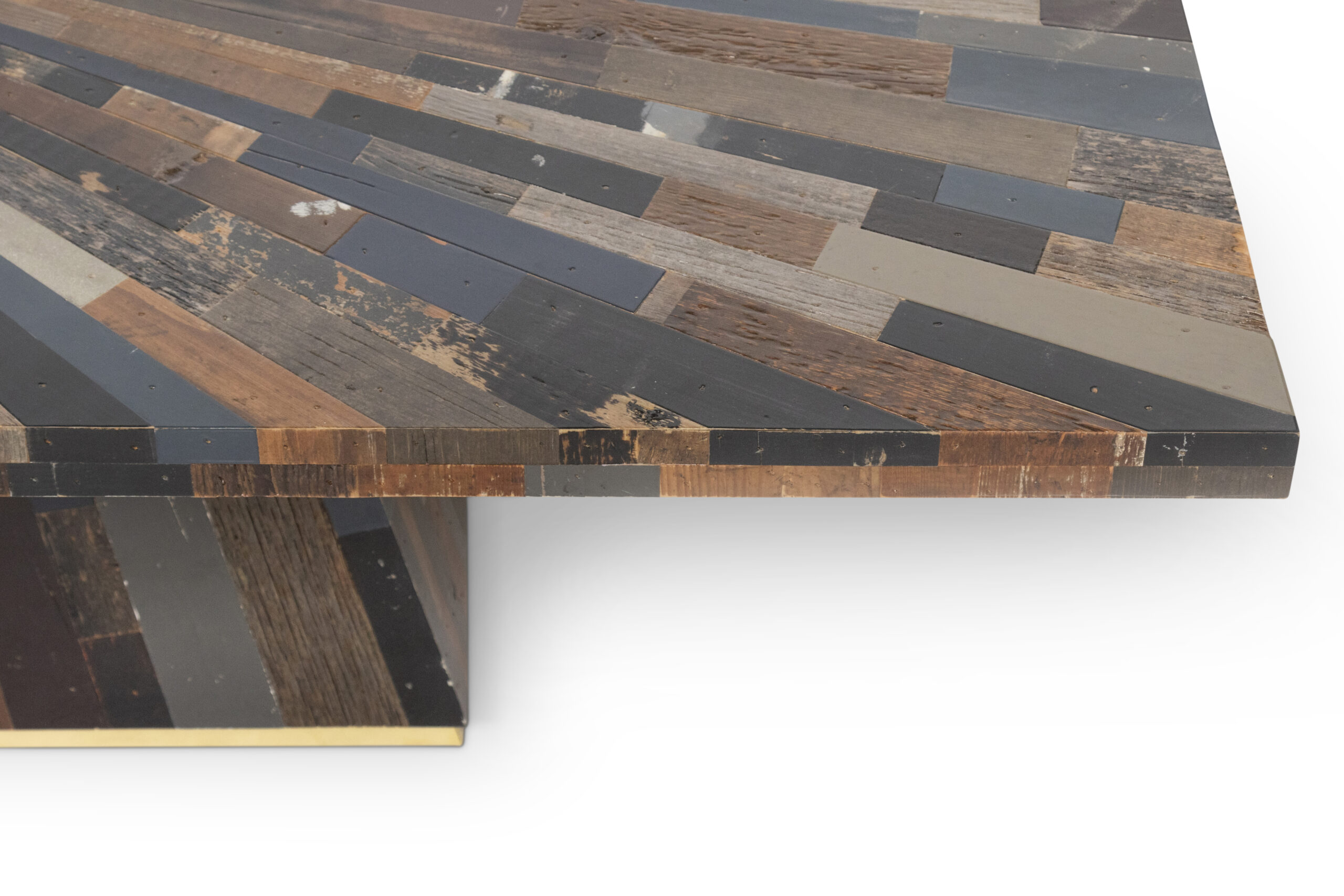

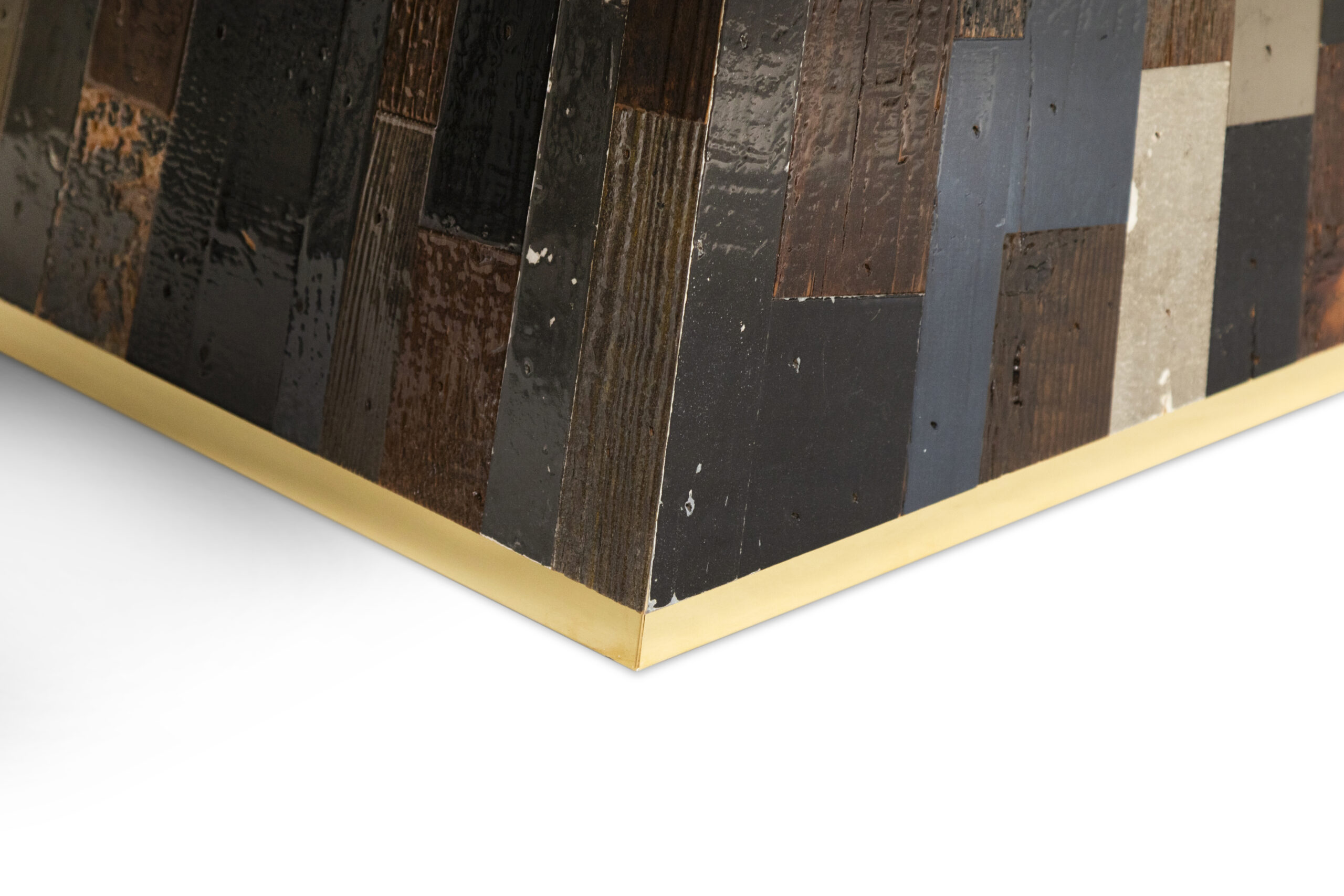

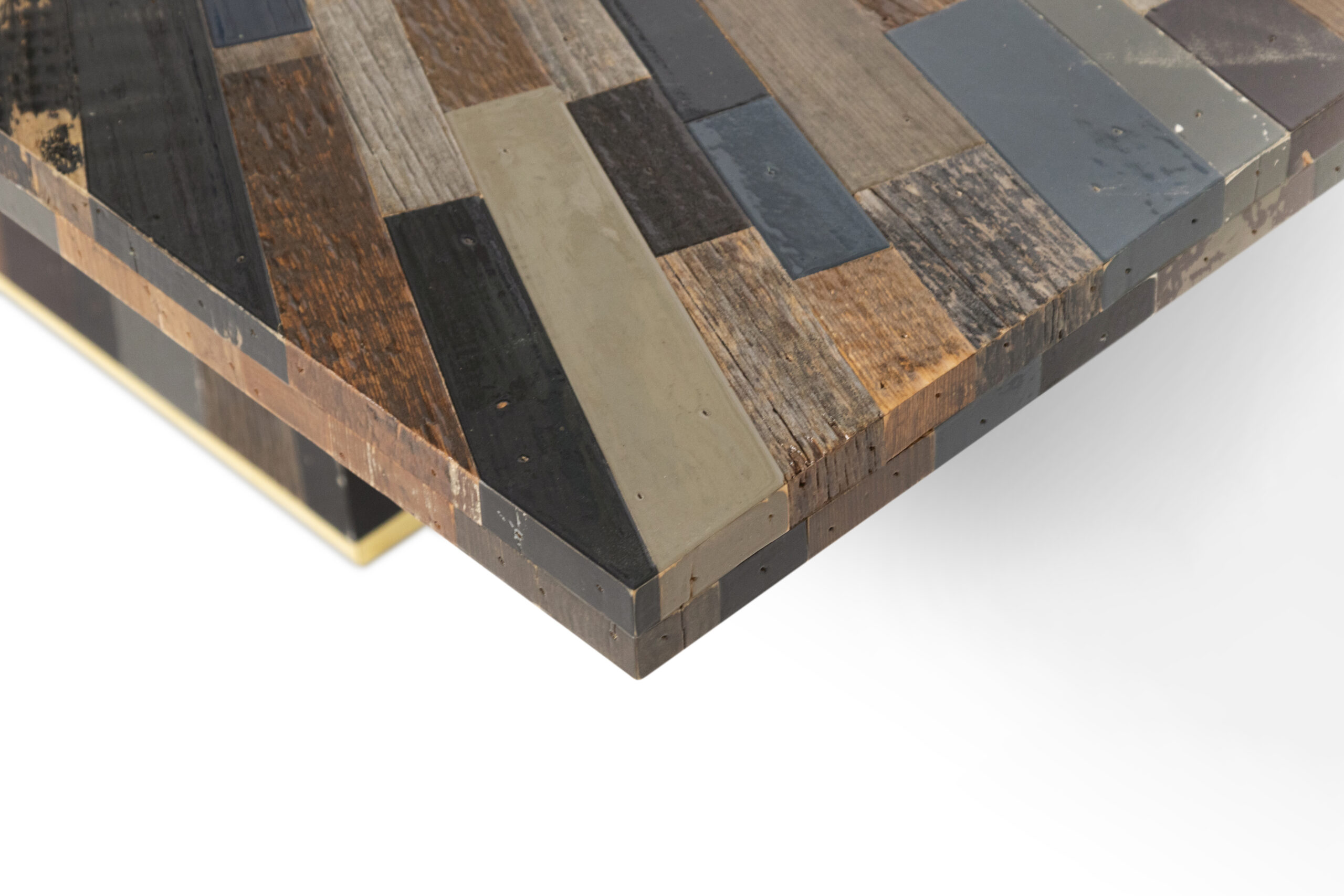

Waste-Waste-Waste Coffee Table in Scrapwood

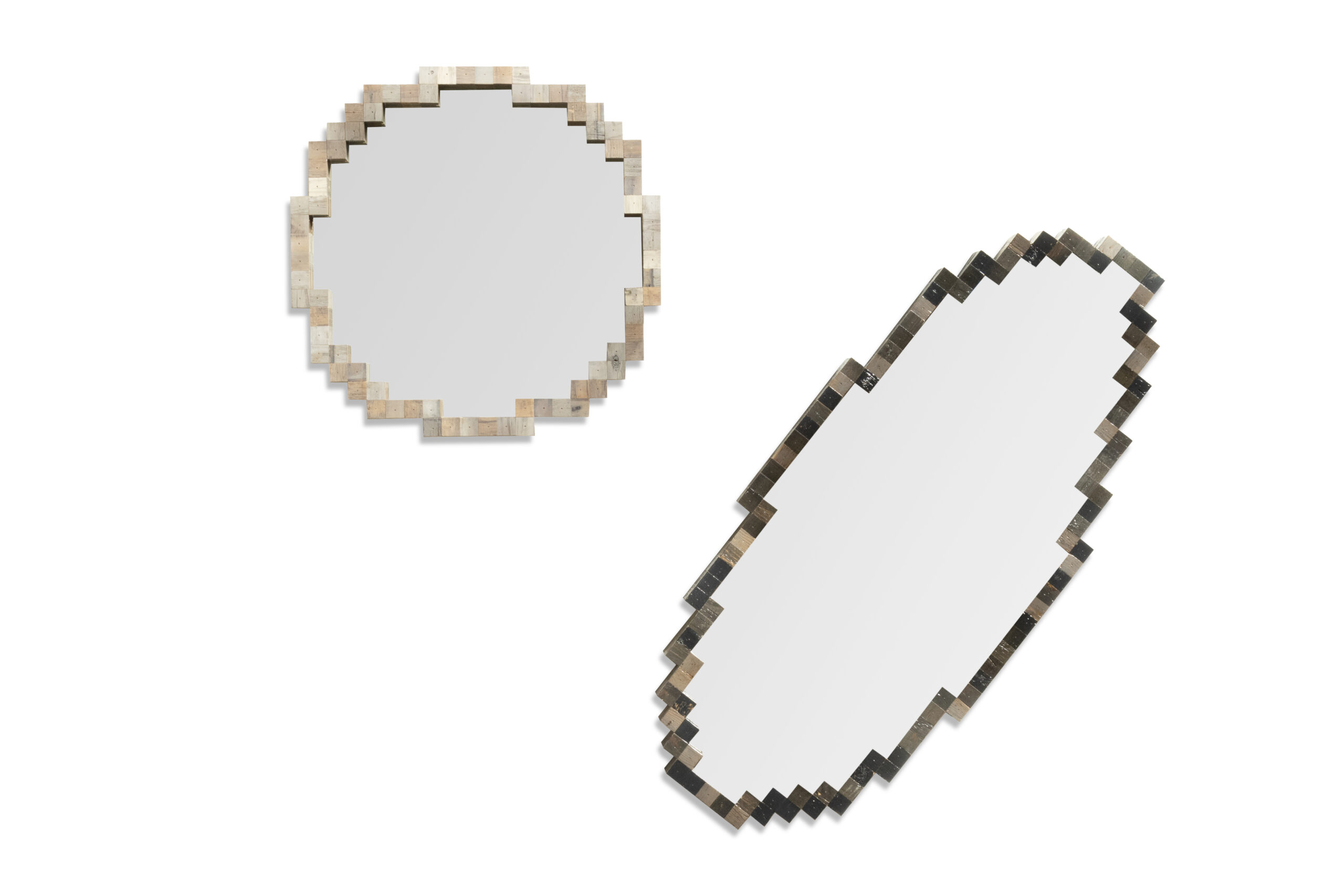

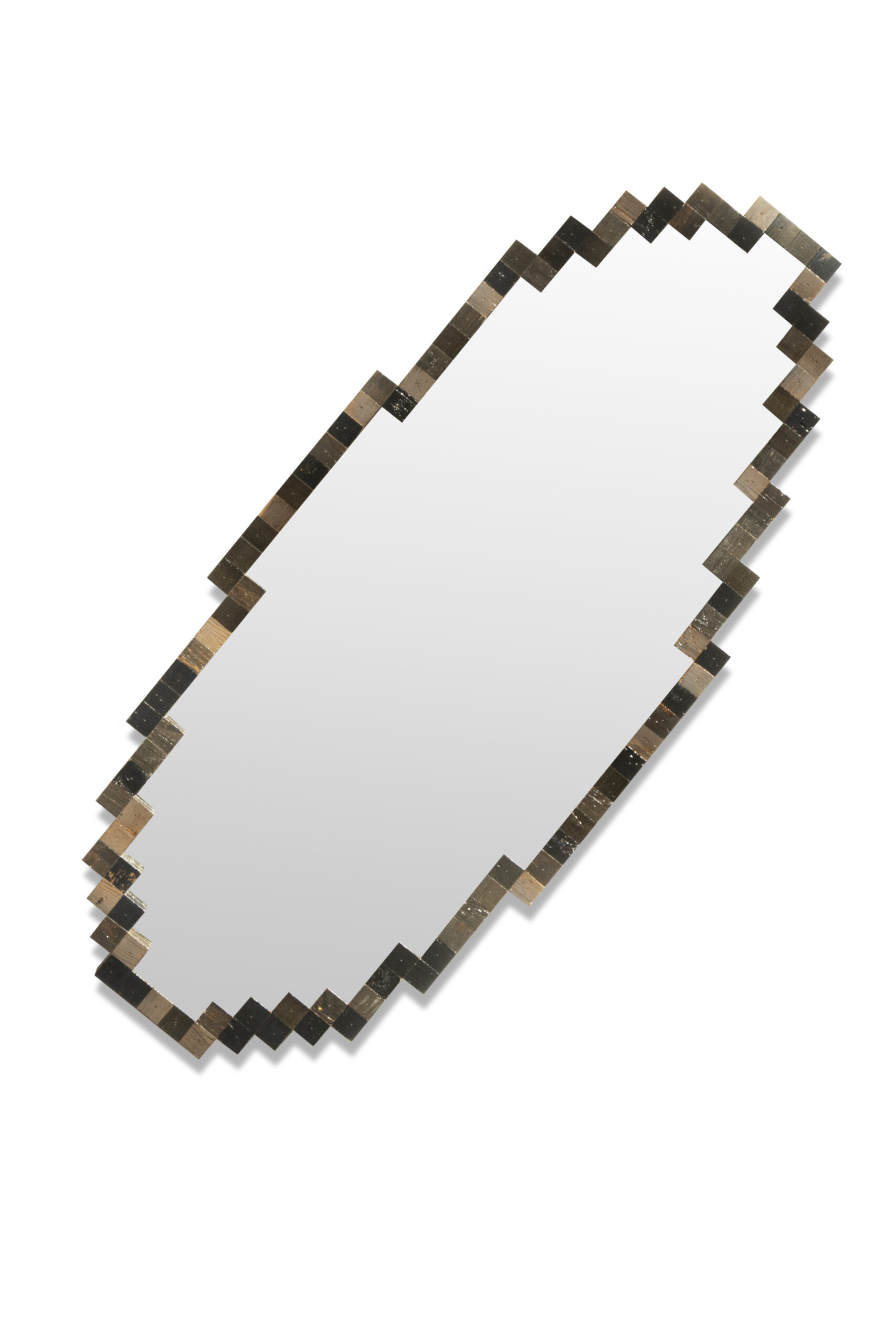

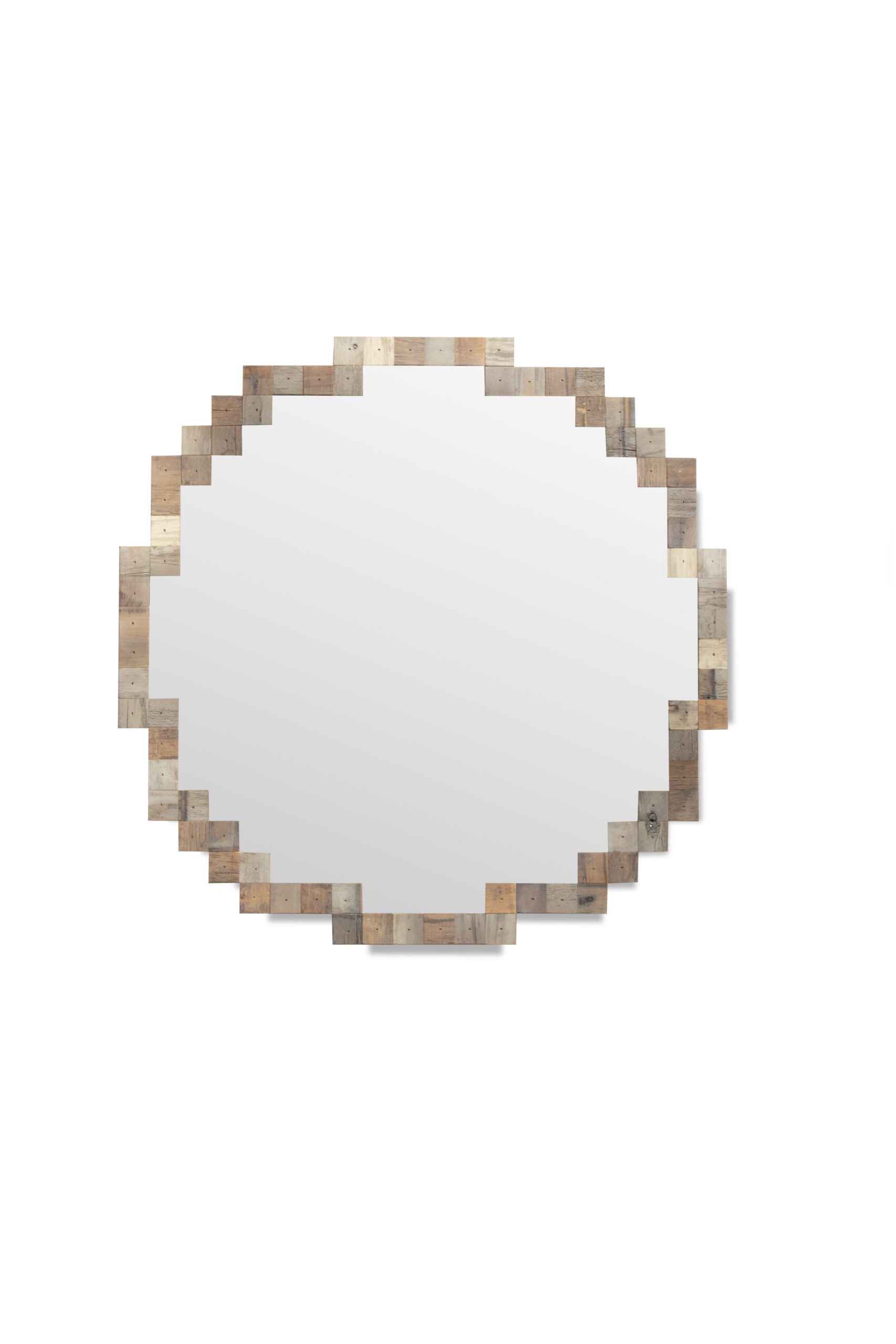

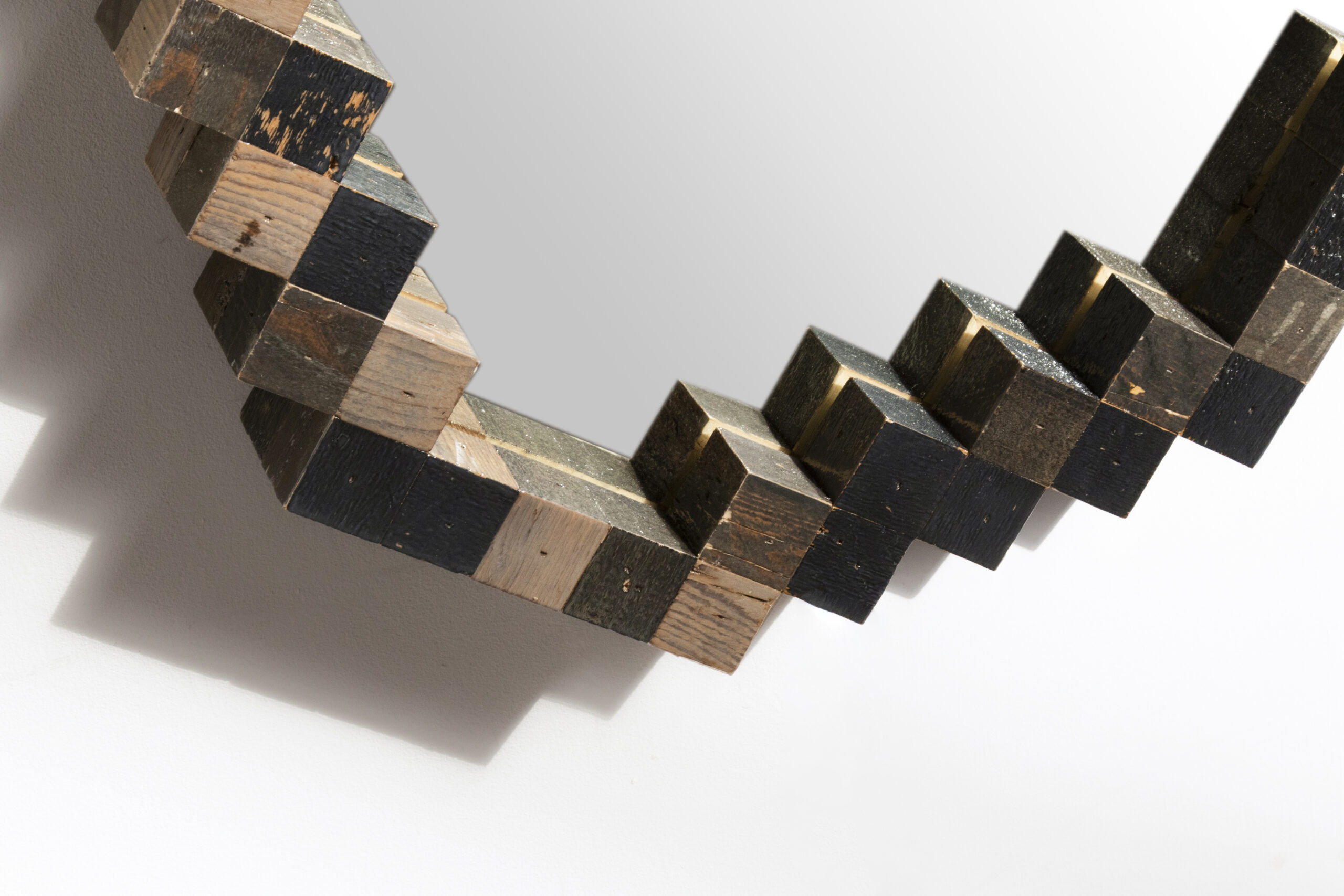

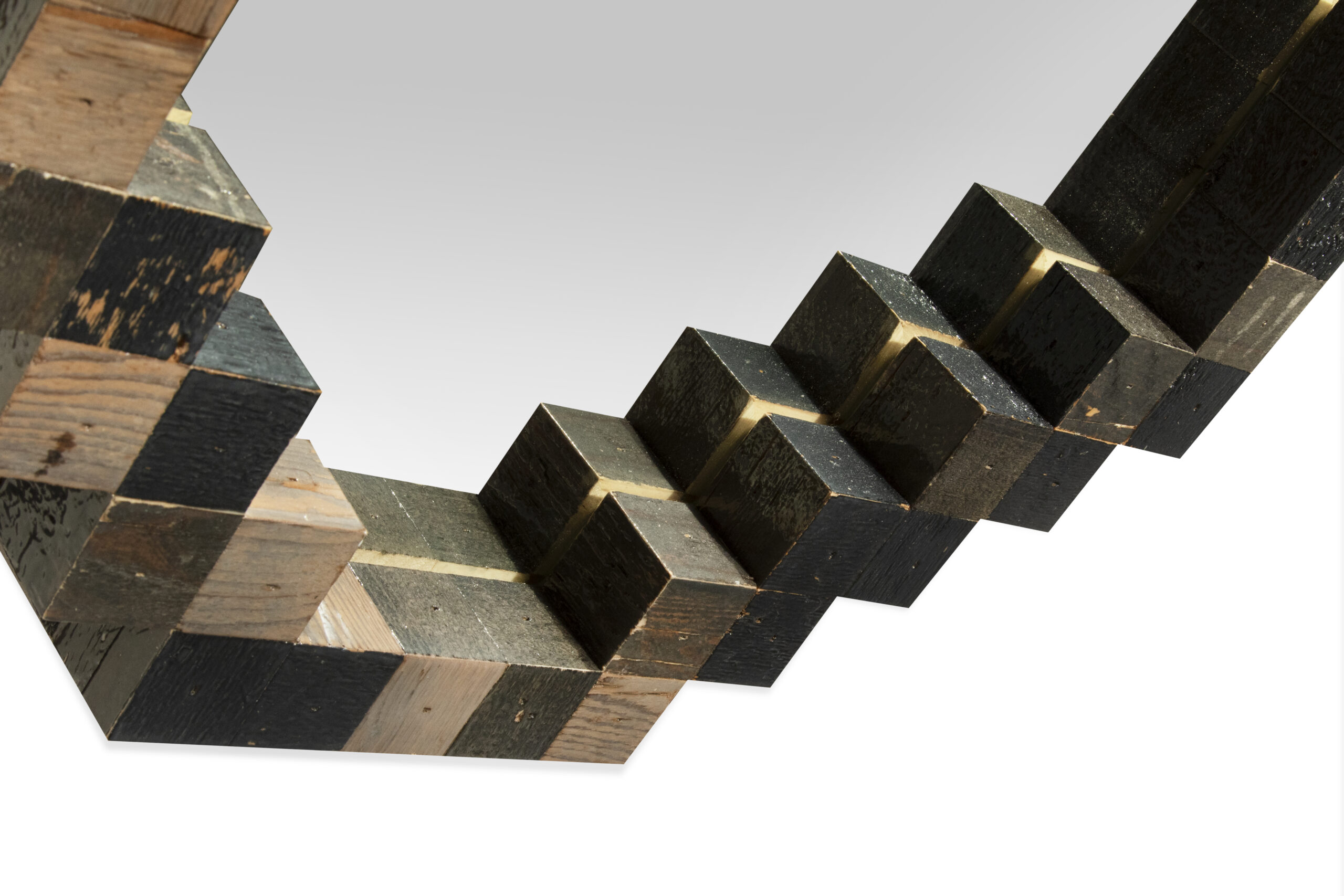

Waste Waste 40 x 40 Mirrors

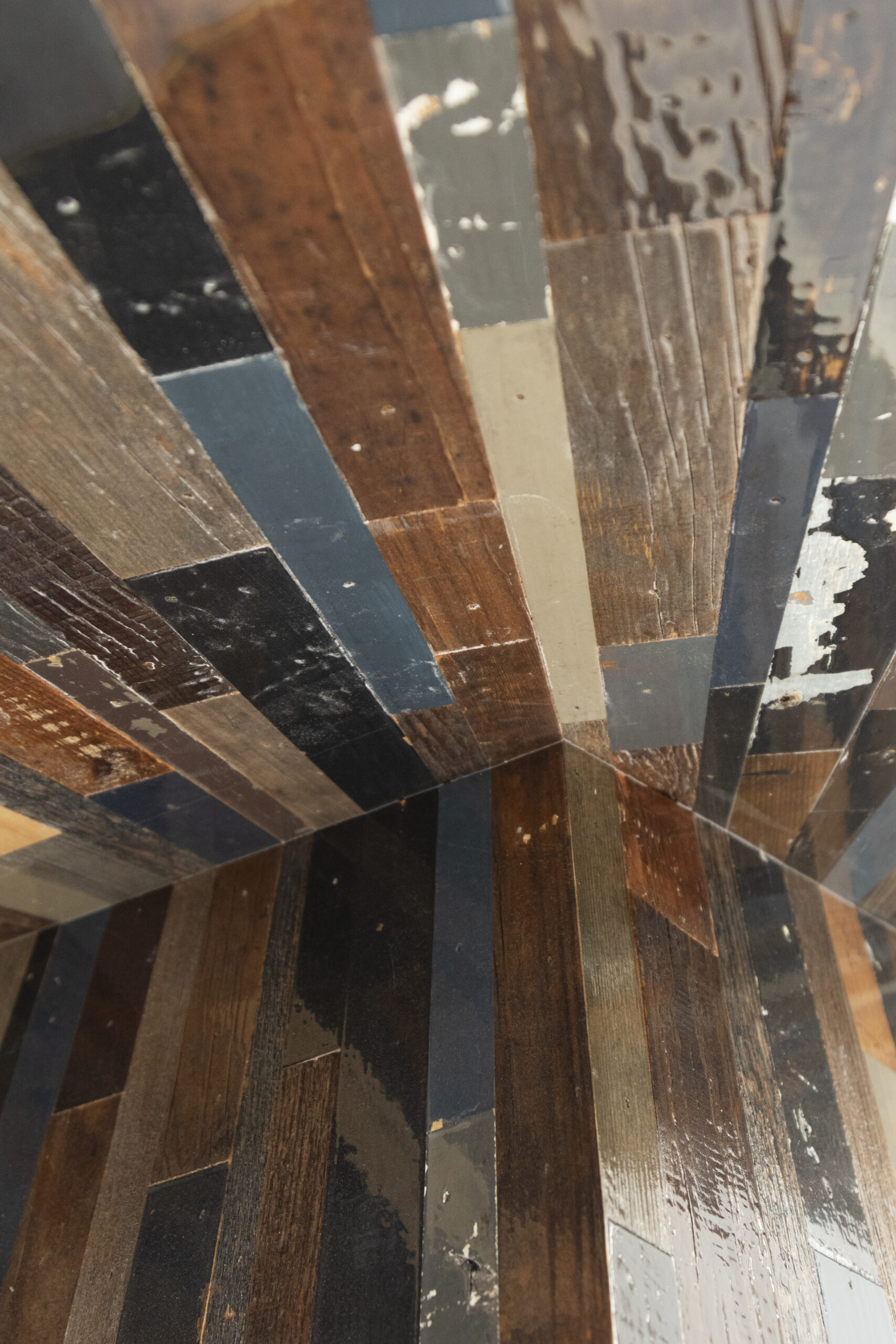

The Waste project came into existence more than ten years ago as a reaction to the annoyance of having to throw away material because it was too expensive to do anything with it. Not because it was worthless, but because labour costs so much.

The game of turning daily reality around and pretending that labour is free and materials are worth their weight in gold resulted in products that are, in theory, unsalable (because labour is not at all free) but in practice, the products turned out to be saleable after all. As opposed to almost any other product, the Waste products are made with the patience of a saint, quite a feat considering this is an age in which time is a rare commodity for pretty much everyone.

However this process, too, leaves waste material behind, in smaller amounts, and more difficult to use than our ‘usual’ waste material. This ‘waste from waste’ motivated us to take it a step further. In an effort to bridle the process to some extent, and keeping in line with the metal waste products, I came up with the idea of employing a fixed size of 40 mm x 40 mm.

This size, combined with the decision to use the materials solely as an outer skin instead of stacking them, particularly defines the appearance of the products. Straight-edged shapes are formed which are always a multiple of 40 mm, and round is therefore not round. Just as with the beam and tube furniture, the objects are numbered consecutively, and no two pieces will be identical.

Old Oak Tile Dresser

This cabinet is the last in the old oak series, we ran out of wood. Years ago, we swapped a batch of sawn logs that had lain in a farmer’s barn for decades. The wood was rock hard (oak hardens over time), cracked and discoloured. Some logs were more wretched than others. In the end, the worst wood remained and from that, as we so often do, we made the most luxurious product. Bad is just how you look at it; it takes a lot of time to make something with it, but the older the oak, the nicer the colour and texture.

We scrape and saw the wood and make 20 x 20-centimetre tiles and clad the cabinets with them. The design is of deceptive simplicity; the size of the tile determines the size of the cabinet. The three cabinets therefore differ only in their proportions. Behind the tiles is a whole world. To open the cabinet, we created a tilting system hidden behind a tile. You have to know or try which tile is the one that tilts.

If you press your hand against the tile, it gives way and the door or drawer on the tile above it can be opened. The double pull-out wooden drawer runner that we developed ourselves (I wrote a separate piece about that earlier) ensures that the drawer opens smoothly all the way. For the doors, we specially developed a brass hinge. A drawer consists of about 30 parts. The image of the cabinet is minimalist, but on closer inspection, there is no doubt that maximum attention has been paid to it.

Tube Lounger

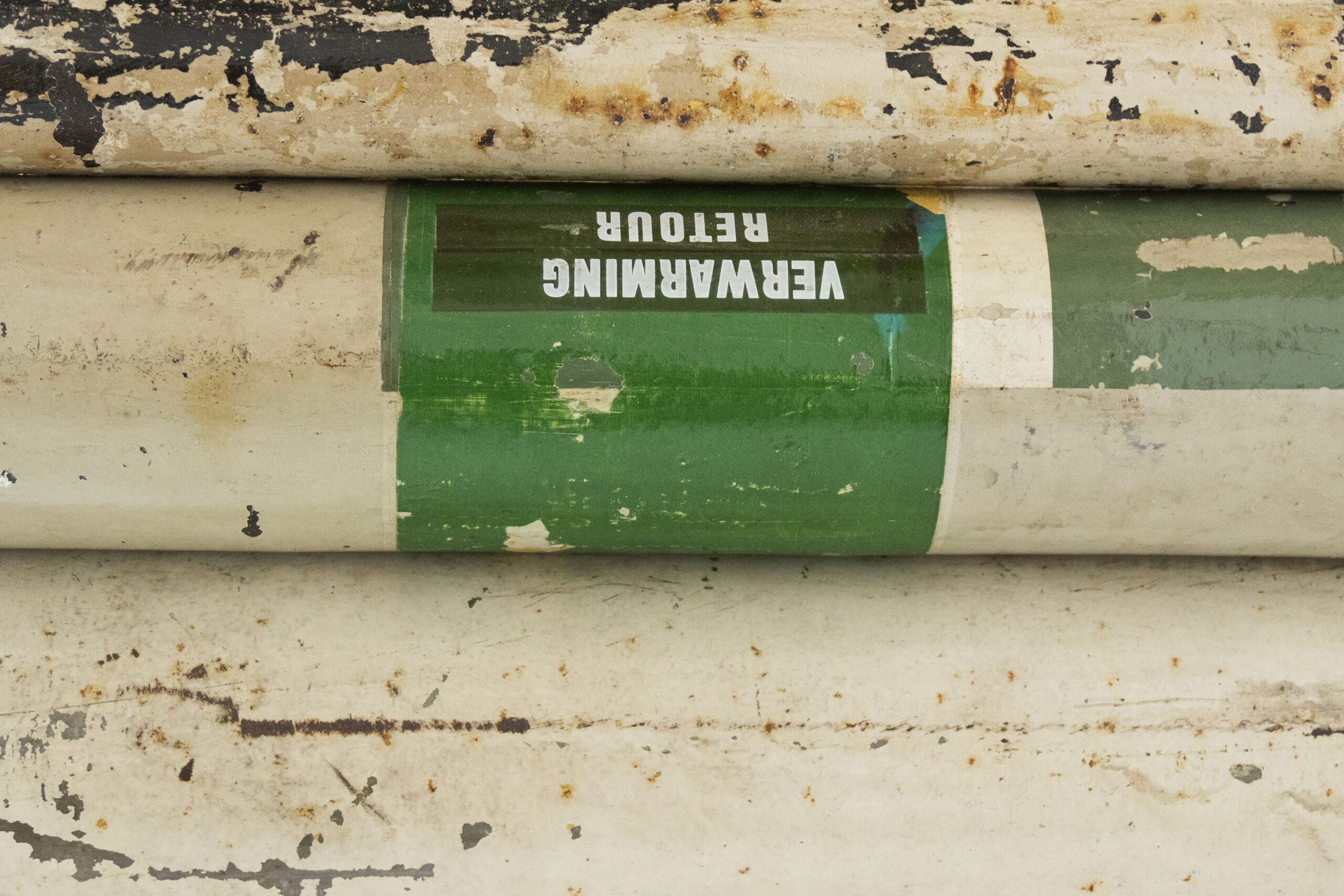

After stacking the enormous beams it was a logical step to start stacking the piping we had in stock. The difference is that pipes roll, therefore we decided to attach them together using nuts and bolts at

the ends of each pipe. This turned them into seating objects that could be disassembled. The tubing was fixed together only after each element had been held in place with clamps absolutely right to create a perfect seat.

After the piles of straight pipes we had removed from our building during demolition, and which we had used to make the benches and armchairs, there were also still curved pieces. With these pieces it is possible to construct. We made tables and chairs from them. The tables were finished with old beams table tops, and the chairs were upholstered with fabric taken from the awnings of the Philips buildings that were being demolished around us.

This tube lounger is custom made for The Future Perfect.

RAG Chandelier

New RAG Vases

This post is also available in: NL

« Back to blog