The tile cabinets

After Jeanine and I created the first tile cabinets back in 1993, we created another series, of pillar cabinets. In the years that followed, our joint production efforts were limited to our three daughters, who, one by one, made it impossible for Jeanine to work professionally in any capacity. Right when the clay was made and the mixer was in the barrel, we’d get a call that one of the children had a bad cough or, for some other reason, needed to be picked up from day care or school. As the children grew older, it slowly but surely became easier to resume working together. Whether or not by coincidence, we suddenly started receiving more orders for our ceramic cabinets: pillar cabinets in all the colours of the rainbow, and cabinets with birch, aluminium and porcelain, as well as an order from Roberto Polo to design a dual set of tile cabinets in black and white, wood and steel. We decided to make both cabinets in a series of three.

What I like to call my ‘puzzle period’ culminated in a grand finale with the cabinets (the puzzle period was the period in which I was working on the stairwell solution for the Westergasfabriek and on the interior of the National Glass Museum). In previous years, due to the desire and necessity to develop affordable products and objects, I had become more and more adept at putting together three-dimensional structures in a simple manner. Little by little, the structures became more complex and increasingly detailed, hence the ‘puzzle’ reference.

A kind of infrastructure was created on the inside of the cabinets, so that the drawers and fronts could be placed as desired. This infrastructure was almost impossible to devise, so we ultimately decided to make the details one by one and then assemble them afterwards. These are cabinets in which not only Jeanine’s decorative side converges with my austere and pragmatic side, but also in which simplicity of detail due to quantity leads to complexity, only to once again result in a stark bearer of decorative ceramic elements.

Box inside a box inside a box inside a box

These boxes are made of a single piece of wood. By sawing off a slice around the wood each time and then shaping the slices and gluing them back together, you can make quite a few boxes with the only material loss being the saw-cuts. Creating something without material loss or, alternatively, from waste is one of my strongest drives. This originates from a profound love and respect for materials in general. In a sense, this is not really a unique trait, considering the fact that the material is the most important element of any design.

It was a pleasant surprise when nature returned the favour to us, so to speak: the boxes are made in such a way that it is as if you are looking inside the tree trunk and can see how it grew, including a branch that runs all the way into the heart of the tree.

Please click the following link for the short movie of André Amaro and Piet Hein Eek.

The plate glass cabinet

This cabinet is a sort of rationalised version of the cupboard we previously made out of dark scrap wood. What makes this cabinet so unique is that the sides are also made of glass, making it possible to see right through it. By ‘rationalised’ I mean that exactly one sheet is used and the cabinet can be disassembled for compact transport. The abstraction of the idea makes the cabinet more of an architectural design than a productdesign, thereby resembling the 99.13 and 97.5 percent cabinets, which are also made out of exactly one sheet.

Aluminium furniture

I came up with the idea for the first aluminium furniture back in 1993 for a law firm housed in a magnificent canal-side building in Amsterdam. The aluminium collection was born not long thereafter. We occasionally sold a piece, the crowning touch being the delivery of a large number of chairs, stools and tables to the MoMA in New York. Sales declined more and more after that, which led me to often joke that the sales of the collections would not pick up until after I was gone, giving the children plenty to look forward to. After all, I’ve never doubted the timelessness and quality of the collections.

But aluminium appears to be coming into favour well before my demise (hopefully) and sales have suddenly improved. Reason enough to dust off the armchair and sofa (which, incidentally, never were big sellers), reupholster them and offer them a second chance. The time is simply ripe for this. Otherwise, we’ll simply revert to the inheritance scenario once again.

The entire aluminium collection was the result of me walking into a factory which held a punching machine for the first time. The machine is a kind of robot that pulls thin sheets of metal under a punch, which then creates various shapes. By folding the parts and assembling them, you can make all kinds of three-dimensional shapes. I was fascinated by both the materials and technical possibilities.

Sharpener collection

Decent production is the basic principle behind the Munio brand. I find it quite remarkable, really, that so much production takes place improperly and anonymously that working properly has become something special. Of course, it is always possible to take ideals too far – of which I suspect the gentlemen at Munio – but it is actually a reassuring thought. After toying with a number of ideas, I realised that production in faraway countries is largely determined by schooling and access to capital and goods. A pencil sharpener is probably the cheapest tool in the world and can be used by practically everyone, which is why I came up with the sharpener collection: baskets, organisers, serving trays, clocks and a stool. We will be presenting the first models, which will be available later this year, at the trade show.

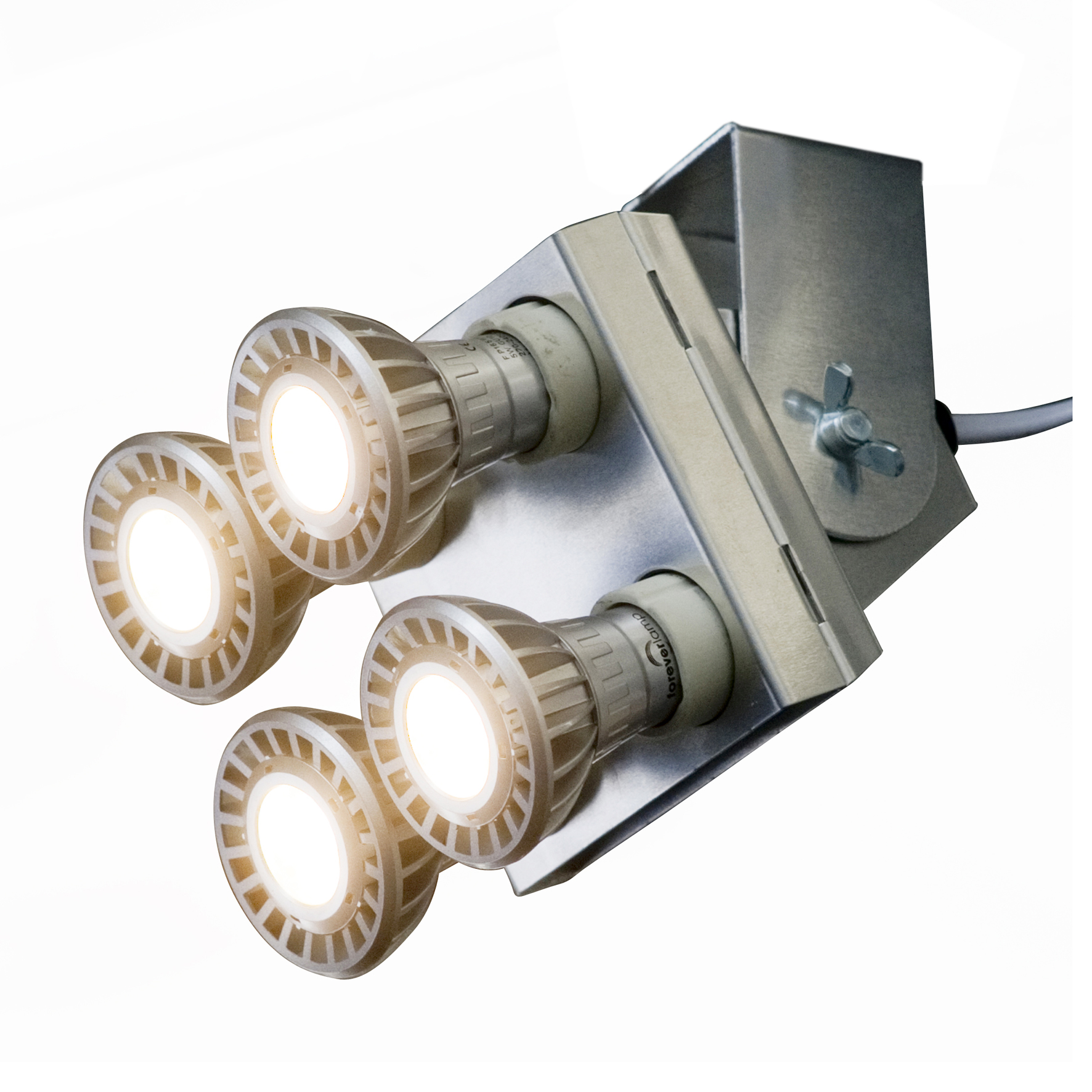

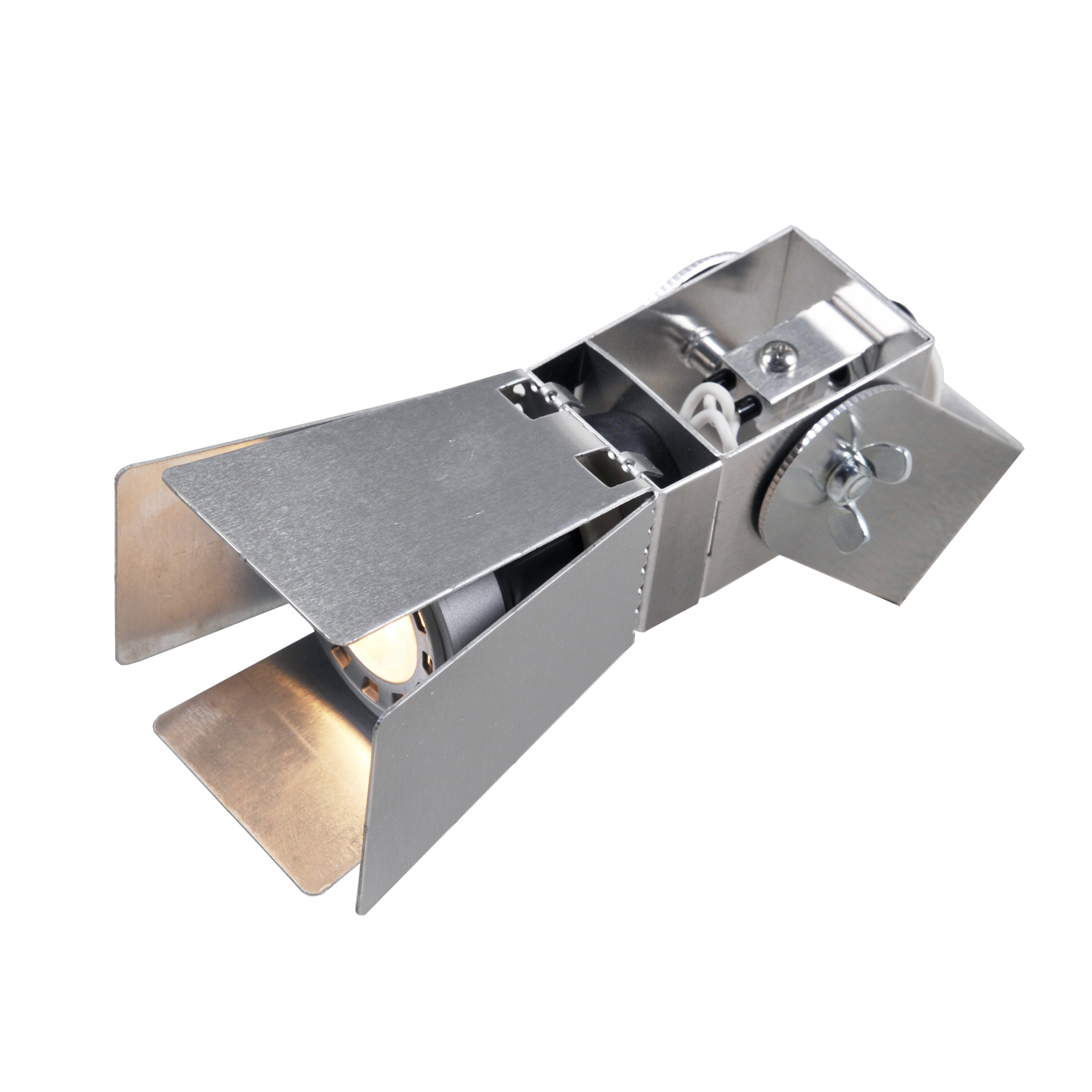

LED 1, 2 and 4 spot

The LED spot is the result of irritation and necessity: irritation over the fact that the halogen lights, which we had to bring with us from the old building due to a lack of time and money, are energy-guzzlers, and necessity because there were far too few.

The new building is much larger, so there were lots of areas in the showroom that were insufficiently illuminated. Thanks to a miraculous deal, we came into possession of a large number of halogen lights, for which I then devised the simplest of brackets, since the fittings had to be cheap, convenient and fast to make. These are the very same conditions you would apply to a lamp to be developed for the market, so it’s not surprising that they began to sell the moment they started brightening the showroom. We’ve simply included them in the collection.

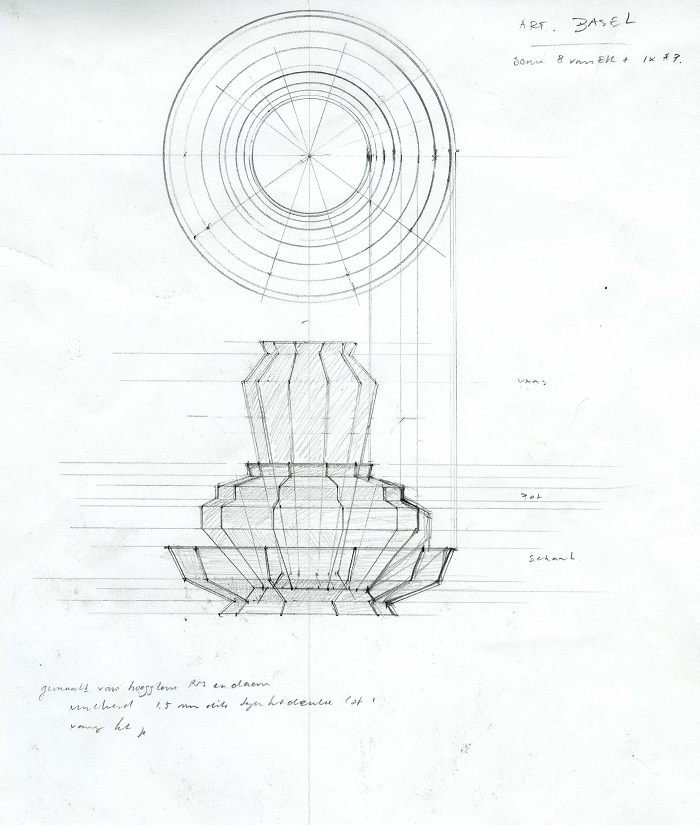

Silver-plated facet vases

The story behind the faceted vases goes back quite far. They ultimately resulted from the flat clay dishes I came up with after seeing my children rolling clay with a pasta roller in my wife’s studio.

Making ceramics is one of the oldest industrial processes on the planet, by which e.g. plaster moulds are used to cast continuously identical products. I found it absolutely fascinating to try to construct with clay as I would with sheet metal. I immediately put together a cup with handle to see if it was possible. It proved to be just that and this was followed by an entire collection of flat clay products.

But when we tried to make pitchers, the clay turned out to be too weak and the whole thing collapsed. It was possible, however, to do this using metal moulds as a sort of scaffolding. The moulds we created became products in themselves. In addition to the ceramic pitchers, we also started making brass silver-plated pitchers. And why not make them even bigger? These bowl and vases are the initial examples from the series of larger objects.

Blue canteentable with Lotty Lindeman’s pink lamp

When we started in 1993, the scrapwood cabinet was our most important iron in the fire. We wanted to sell them to a department store, but that deal fell through because the cabinet on the shop floor was not identical to the one in the warehouse. Admittedly, however, we did not really regret this afterwards. Years later, the same department store was very eager to sell the cabinets, precisely because they were unique and distinctive pieces that were very popular at the time. Thanks to the Internet and digital photography, it was no longer difficult to offer people a choice and to deliver the right product.

Nowadays, we actually make a large percentage of our products to the size and colour specifications of individual customers around the world. In that sense, it is surprising that we did not come up with the bright idea earlier to make the canteentables and other scrapwood products in specific colours. The colours are determined by the batches of wood we’re able to buy. We’ve already presented a white table with a white lamp from Lotty Lindeman. The desire to present Lotty’s colourful lamps with our tables led us to create a blue table with stools under a gigantic pink lamp.

Please click the following link for the catalogue.

This post is also available in: NL

« Back to blog